PTS

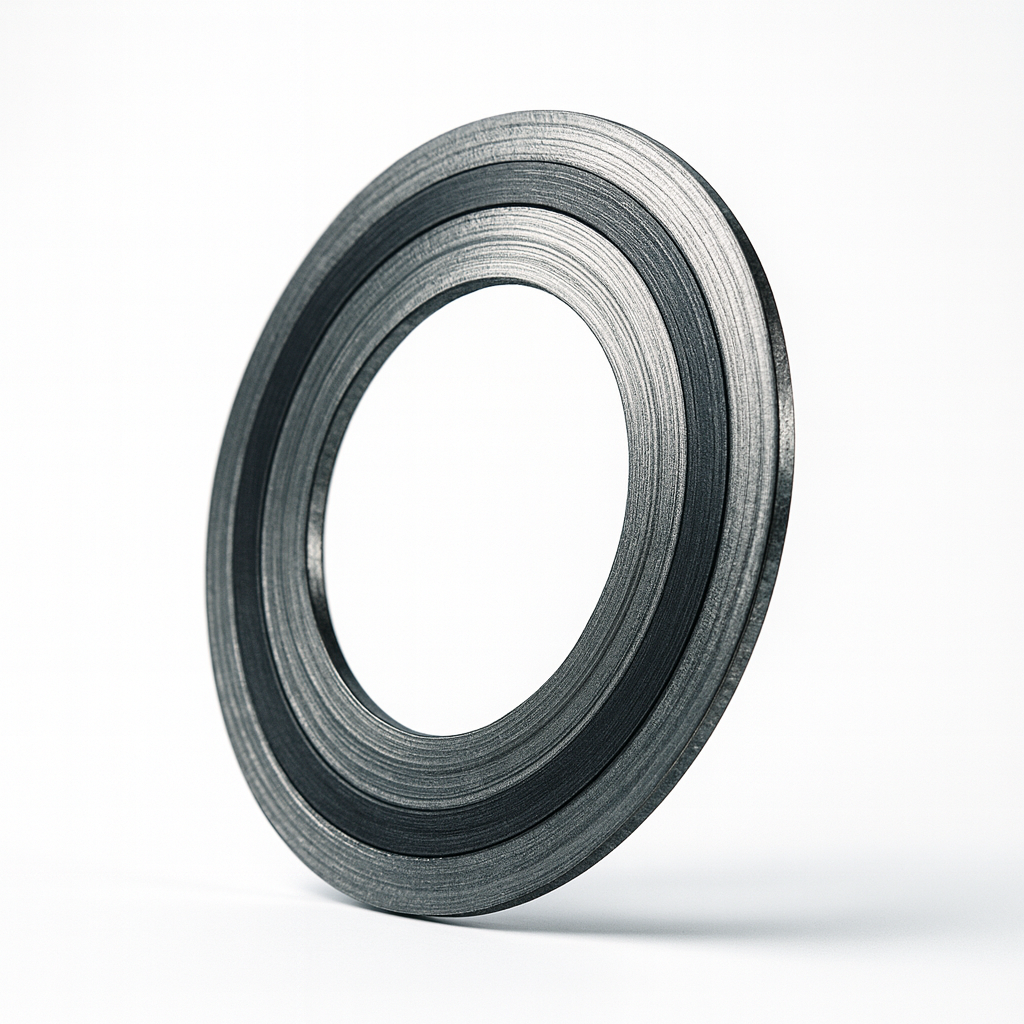

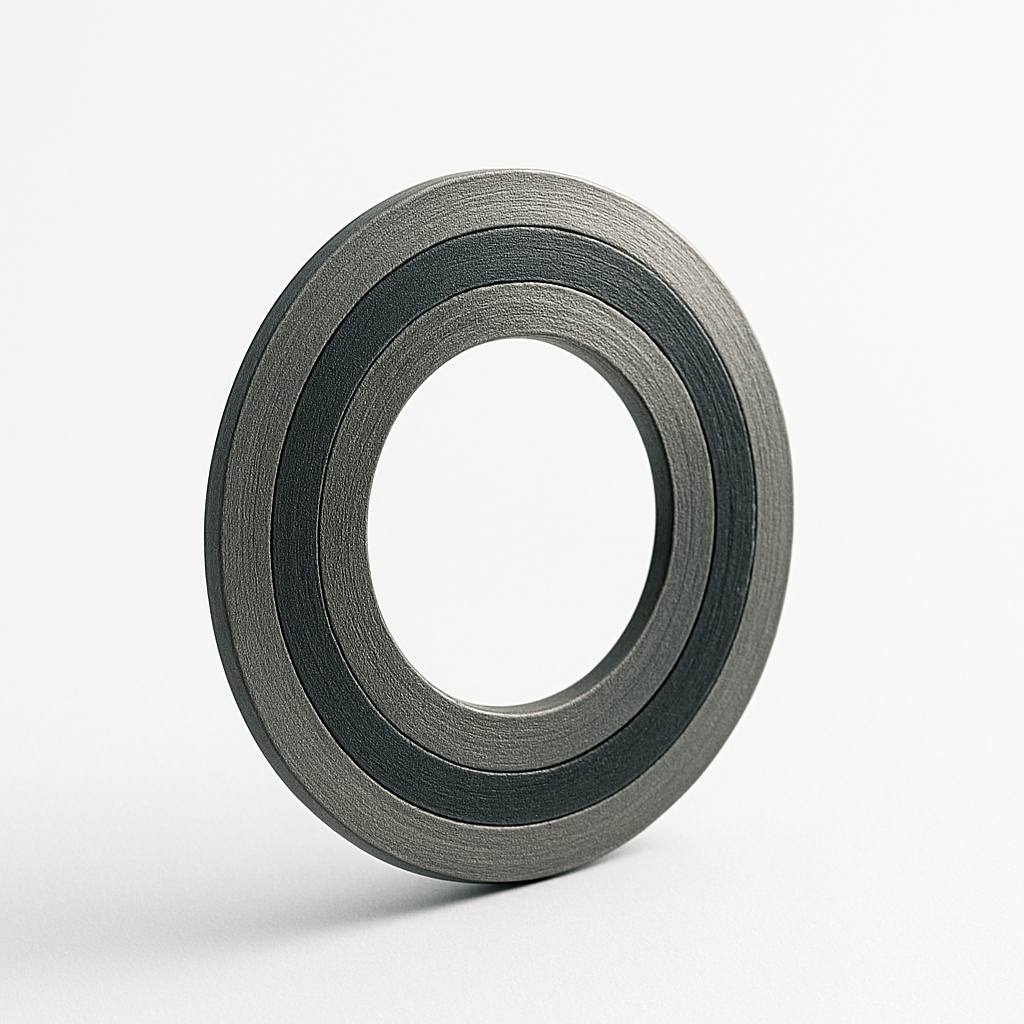

Spiral Wound Gasket Inner Ring

Spiral Wound Gasket Inner Ring

The Spiral Wound Gasket with Inner Ring is a premium sealing solution engineered for enhanced performance in high-pressure, high-temperature, and corrosive service conditions. It features a spiral wound sealing element—constructed from alternating layers of stainless steel winding and soft sealing filler (graphite, PTFE, or mica)—combined with a robust inner ring for additional protection and stability.

The inner ring serves as a reinforcement barrier, preventing inward buckling of the winding under high compression and shielding the filler from direct exposure to aggressive process media. This makes it ideal for applications where media turbulence, high temperatures, or vacuum conditions could compromise seal integrity.

Key Features:

1.Enhanced Durability: Inner ring prevents damage to the sealing element from media flow and heat.

2.Optimal Sealing Performance: Maintains uniform compression and prevents gasket intrusion into the pipe bore.

3.Material Options: Inner ring available in stainless steel, carbon steel, or high-performance alloys to match application needs.

4.Resistance to Extreme Conditions: Suitable for steam, hydrocarbons, chemicals, and corrosive media.

5.Industry Standards: Designed to meet ASME, ANSI, DIN, and other flange specifications.

Applications:

1.Oil & Gas – High-pressure pipelines, offshore platforms, refineries.

2.Petrochemical & Chemical Processing – Acid, alkali, and solvent handling.

3.Power Generation – Steam systems, turbines, heat exchangers.

4.Marine & Shipbuilding – Engine systems and fluid transfer lines.

Share